RDF drying in Edmonton, Canada

2017-06-30

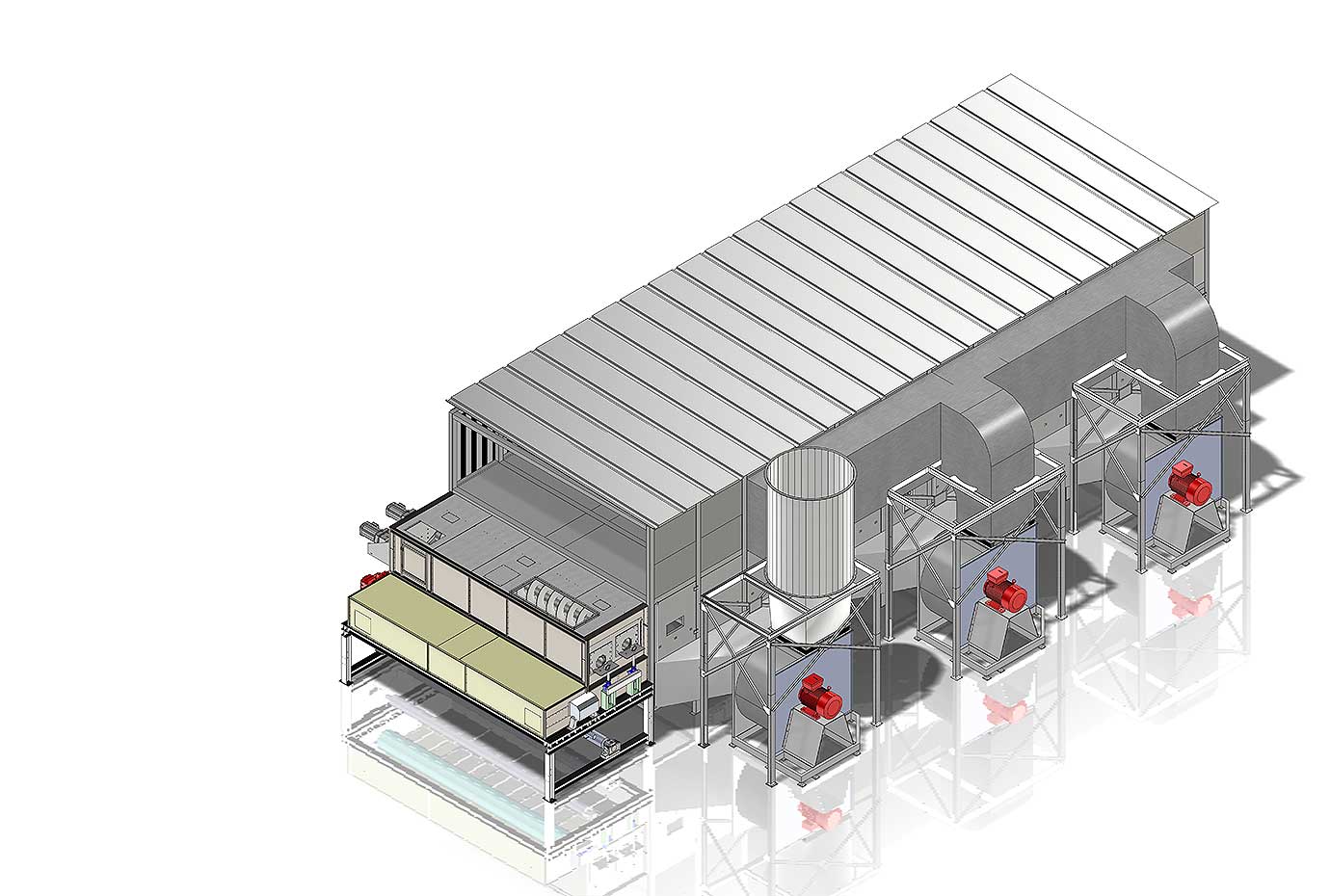

The Edmonton Waste Management Centre (EWMC), owned and operated by the City of Edmonton, is a unique collection of advanced solid waste facilities processing residential, commercial and construction waste. The Integrated Processing and Transfer Facility (IPTF), at the EWMC, is where solid waste arrives and is divided into separate waste streams, including biofuels feedstock production known as refuse derived fuel (RDF).The City of Edmonton has a contract with Enerkem Alberta Biofuels (EAB) to provide 100,000 dry tonnes per year of RDF. During testing, the RDF product has shown to be above the specified range of moisture, which is between 10 and 20% moisture. Berlie Technologies (from Berlie-Falco Group) has been contracted by the City of Edmonton to provide a turnkey solution to reach the targeted RDF moisture content (14% moisture) with an indirect heated belt drying concept from Stela Laxhuber GmbH. Using different sources of energy, waste heat and a natural gas heated boiler system, the belt dryer is able to dry the whole feedstock under varying incoming product parameters. Using a circulation air stream it will reach a high energy efficiency when controlling the air emission. The indirect heated belt dryer based on water / air heat exchangers using process temp below 100°C ensures a 100% secure production with no risk of explosion or fire. The integration of high end security measures such as spark detection and infrared sensors will complete the safety concept of the Stela low temperature belt drying system. The RDF plant is currently capable of producing up to 37 wet tonnes per hour through two processing lines. The RDF plant will operate 16 hours per day and 5 days per week. The addition of a surge bin to store wet RDF will allow for 24 hours per day feedstock delivery to EAB. The dryer has been designed to accommodate these production requirements.

The Edmonton Waste Management Centre (EWMC), owned and operated by the City of Edmonton, is a unique collection of advanced solid waste facilities processing residential, commercial and construction waste. The Integrated Processing and Transfer Facility (IPTF), at the EWMC, is where solid waste arrives and is divided into separate waste streams, including biofuels feedstock production known as refuse derived fuel (RDF).The City of Edmonton has a contract with Enerkem Alberta Biofuels (EAB) to provide 100,000 dry tonnes per year of RDF. During testing, the RDF product has shown to be above the specified range of moisture, which is between 10 and 20% moisture. Berlie Technologies (from Berlie-Falco Group) has been contracted by the City of Edmonton to provide a turnkey solution to reach the targeted RDF moisture content (14% moisture) with an indirect heated belt drying concept from Stela Laxhuber GmbH. Using different sources of energy, waste heat and a natural gas heated boiler system, the belt dryer is able to dry the whole feedstock under varying incoming product parameters. Using a circulation air stream it will reach a high energy efficiency when controlling the air emission. The indirect heated belt dryer based on water / air heat exchangers using process temp below 100°C ensures a 100% secure production with no risk of explosion or fire. The integration of high end security measures such as spark detection and infrared sensors will complete the safety concept of the Stela low temperature belt drying system. The RDF plant is currently capable of producing up to 37 wet tonnes per hour through two processing lines. The RDF plant will operate 16 hours per day and 5 days per week. The addition of a surge bin to store wet RDF will allow for 24 hours per day feedstock delivery to EAB. The dryer has been designed to accommodate these production requirements.